KC Lingerie Ltd.

Knit Concern has a specialized production facility to offer world standard brassiere and brassiere-panty sets. Equipped with 330 specialized brand machines, it can produce about 60,000 pieces of these products per day.

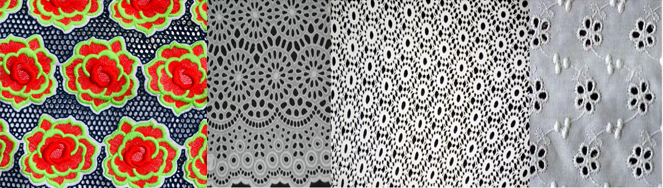

Knit Concern is technologically sound and capable of using value added specialized fabrics and accessories for these wears. It produces synthetic fabrics made with micro fibers for these products .For the same purpose it produces Elastane, Lace, Tricot, Charmese, Satinnet, Power and Net etc as well. However, it uses high quality Combed Cotton Yarn and Lucre from Dupont for fabrics made with Cotton and Cotton-Elastane also.

Warp Knitting M/C and Capasity:

| Type |

Brand |

Nos. |

Capacity |

| Warp kniting Machine |

Tricot, Karl Mayer, Germany |

10 |

7000 Meter/Day |

| Warp kniting Machine |

Raschel, Karl Mayer, Germany |

02 |

1100 Meter/Day |

| All Over Lace M/C(ML 46) |

Lace, Karl Mayer, Germany |

01 |

800 Meter/Day |

| Double Needle M/C |

Double Face Fabric, Karl Mayer, Germany |

02 |

1000 Meter/Day |

KC Lingerie Synthetic Dyeing Unit:

| Process Name |

Capacity |

| Dyeing (Open Width) |

3 Tons/Day |

| Finish (Open Width) |

9 Tons/Day |

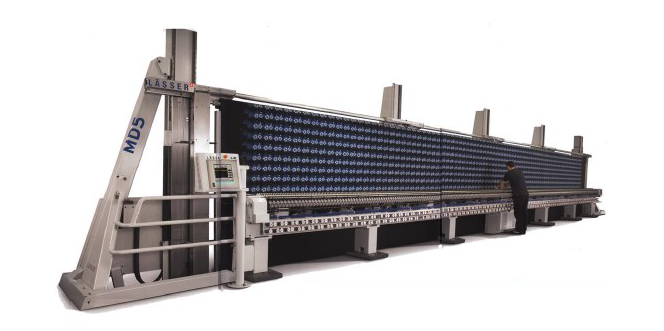

Lasser Schiffli Embroidery:

| Type |

Brand |

Nos. |

Capacity |

| Schiffli Embroidery Single Color |

Lasser, Switzerland |

04 |

7000 Yard/Month |

| Schiffli Embroidery Multi Color (Color Limitation : 4 Color Max) |

Lasser, Switzerland |

1 |

4000 Yard/Month |

Reggiani Digital Print M/C and Capacity:

| Inks |

Composition |

Capacity |

| Acid |

Nylon/Polyamide |

2,50,000 Meter/Month |

| Reactive |

Cotton, Viscose |

12,000 Meter/Day |

| Sublimation |

Polyester |

3,000 Meter/Day |

Narrow Knitting M/C and Capacity:

| Type |

Brand |

Nos. |

Capacity |

| Needle Loom |

Comez, Italy |

38 |

24,70,000 Yds/Month. |

| Jacquard |

Comez, Italy |

34 |

10,60,000 Yds/Month. |

| Crochet |

Comez, Italy |

15 |

11,70,000 Yds/Month. |

KC Lingerie Sewing Line and Capacity:

| Inks |

No of Sewing Line |

Production Capacity / Month |

| Boys and Mens Underwear |

30 |

18,00,000 Pcs/Month |

| Girls and Ladies Panty and Nightwear |

15 |

09,00,000 Pcs/Month |

| Bra & Swimwear |

12 |

04,00,000 Pcs/Month |

KC Lingerie Product Line:

Buyer of KC Lingerie:

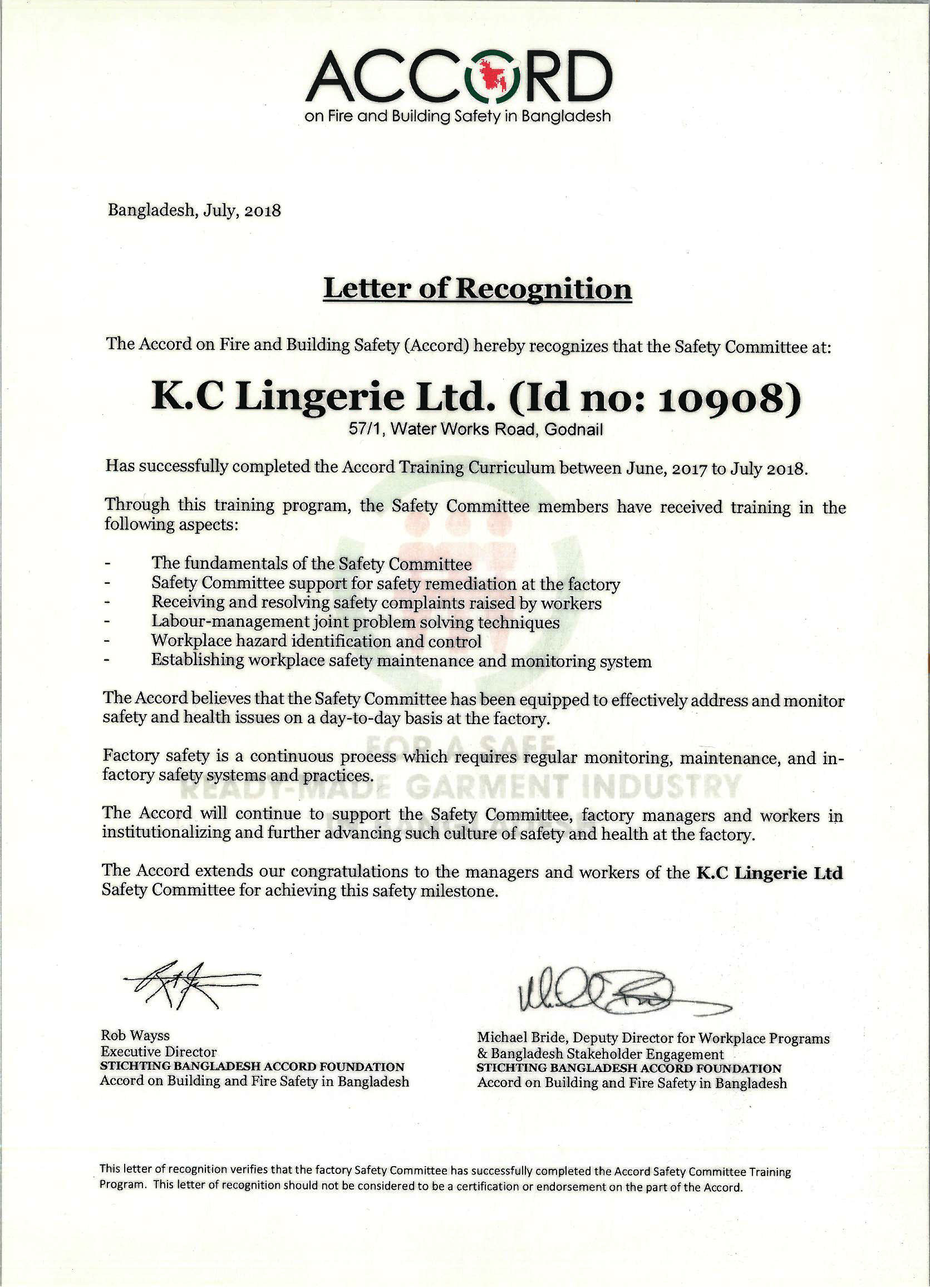

Certifications: